Consumable Materials” is a broad term encompassing a wide range of products used in various industries and everyday life. These materials are designed to be consumed or used up in the process of performing a task or achieving a goal. They play a vital role in numerous sectors, including manufacturing, healthcare, hospitality, construction, and more.

In manufacturing, consumable materials refer to items such as raw materials, components, lubricants, adhesives, and solvents that are used in the production process. These materials are essential for creating finished products and are consumed during manufacturing operations.

In the healthcare industry, consumable materials include medical supplies such as bandages, syringes, gloves, disinfectants, and disposable medical instruments. These materials are crucial for patient care, infection control, and medical procedures, and they are typically single-use items to prevent cross-contamination.

Choosing consumable materials is crucial for several reasons:

Assessing the quality of consumable materials is paramount. This involves evaluating factors such as durability, performance, reliability, and consistency. High-quality materials ensure optimal outcomes and minimize the risk of defects or failures.

Cost considerations are essential when selecting consumable materials. While quality often correlates with price, it's important to strike a balance between upfront costs and long-term value.

Control systems encompass Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and Supervisory Control and Data Acquisition (SCADA) systems. These systems monitor and regulate industrial processes by collecting and analyzing real-time data.

Consideration should be given to how consumable materials impact customer satisfaction. In customer-facing industries, materials that enhance the user experience, such as comfort, aesthetics, or convenience, contribute to customer satisfaction and loyalty.

The choice of consumable materials reflects on the reputation and credibility of a business. Consistently selecting high-quality, safe, and environmentally responsible materials enhances brand reputation and fosters trust with customers

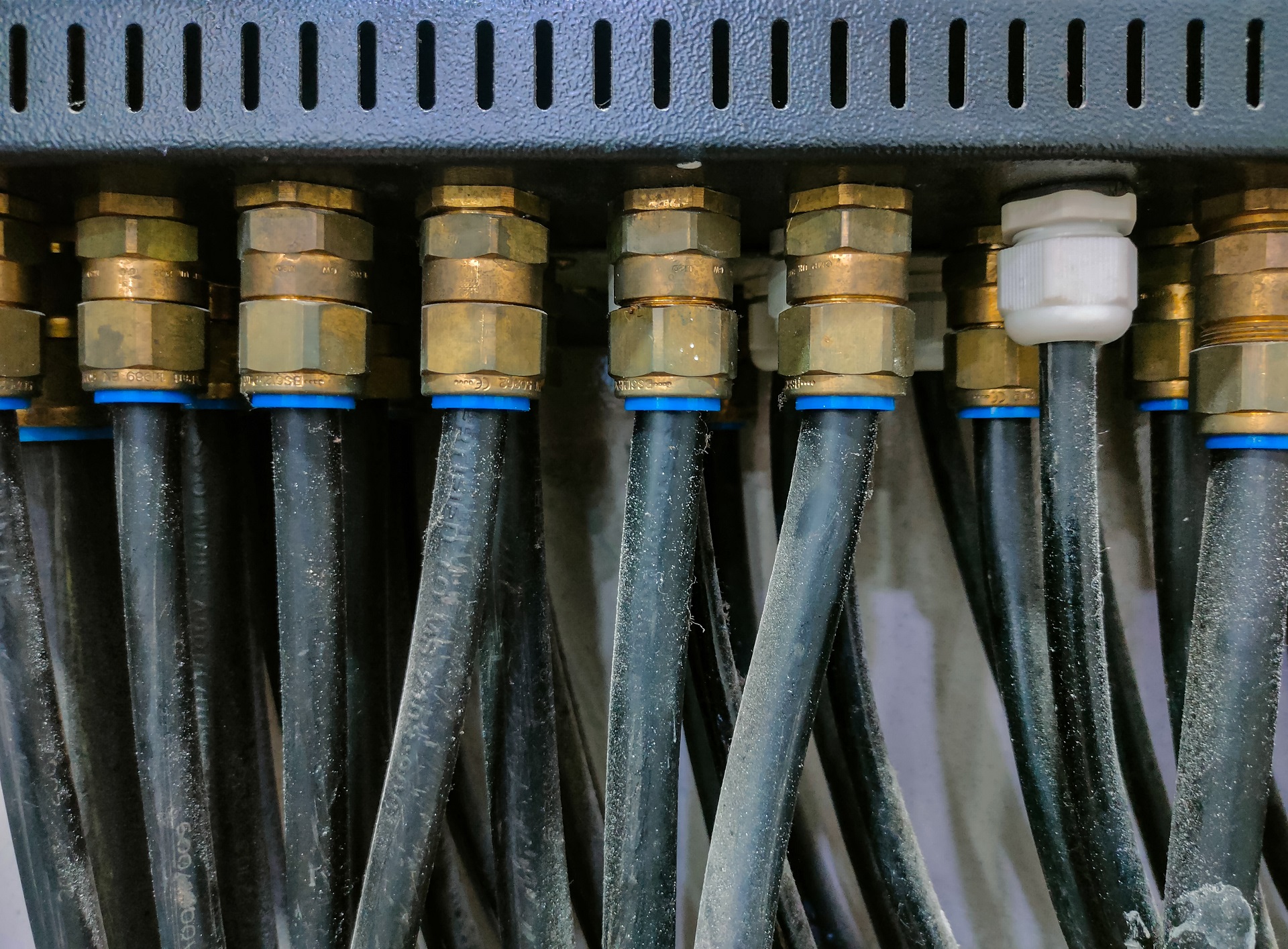

Control valves regulate the flow rate, pressure, and direction of fluid in pipelines to maintain desired process conditions. These valves play a vital role in process control loops, ensuring precise manipulation of flow parameters for optimal system performance.

Connect with Nayak Energetic Associates and experience the power of collaborative success. Let’s energize possibilities and shape a dynamic future together.

Nayak Energetic Associates stands as a pioneering force, specializing in the seamless convergence of innovation, precision, and excellence.

Copyright © [year]. All rights reserved. Design By Technomantra.